-

-

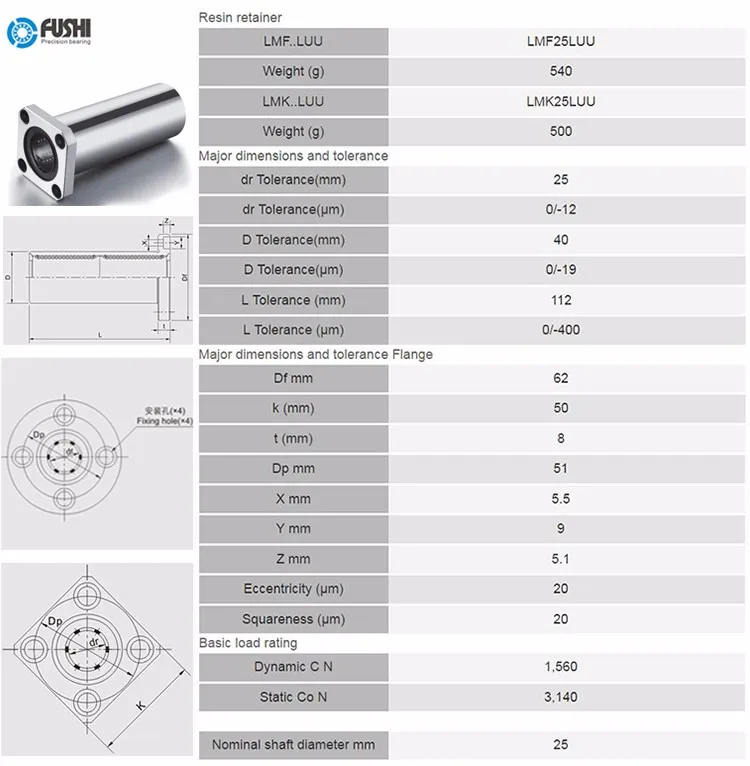

Product name: LMK25-LUU square flange long linear ball bushing bearings

-

-

Price: ASK

-

-

Post date: 2020-07-29

-

-

Stock Quantity: 800

-

Linear Bearings LMK25-LUU Precision P

Model: LMK25-LUU

Categories: FLANGE TYPE LINEAR BEARINGS > LMF-L LMK-L LMT-L SERIES >

Description:

The square flange type linear bearing mainly consists of sleeve, ball, seal, nylon cage and square flange. Among them, the flange plays a fixing role. During installation, the coordinated equipment should have high bore accuracy.

The product is finely processed enjoying low coefficient of friction. This also allows it make almost no noise during working. Due to the reasonable design, the flange has good stability. In addition, the product also features high working accuracy. With easy replacement, it has been widely used in CNC machine tools, printers, power tools, sports equipment, multi-axis machine tools, and so on.

The sub-categories of this product are almost similar in the appearance and functionality. However, LMK, LMEK, and LMBK series are produced in accordance with the standards in Asia, Europe, and the Americas. With a wide range of size ion, it can be suitable for different machines. In addition, UU type is a common square flange type linear bearing, while the LUU type refers to the lengthened one.

Related Names:

Square Flange Linear Ball Bearing | Linear Motion Bushing | Square Flange Linear Bushing

Here is the technical specification of LMK25-LUU LINEAR BEARINGS as below:

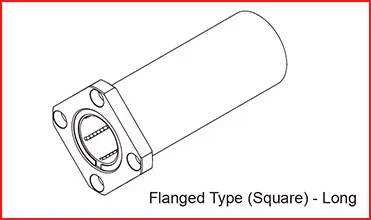

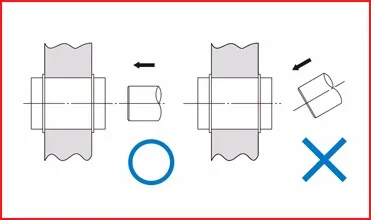

Flanged Type (Square) - Long

Like model LMF-L, this type also has a flange, but the flange is cut to a square shape. Since the height is lower than the circular flange type, compact design is allowed. Containing two units of the standard retainer plate, this type is optimal for locations where a moment load is present.

As a China-based square flange type linear bearing manufacturer and supplier, FUSHI also offers oval flange mounted linear bearing, linear shaft, support rail, adjustable type linear bearing, and much more.

Warm Reminder

Shipment:

When you place an order, please choose a shipping method and pay for the order including the shipping fee. We will send the items within 3 days once your payment is completed.

We do not guarantee delivery time on all international shipments due to differences in customs clearing times in individual countries, which may affect how quickly your product is inspected. Please note that buyers are responsible for all additional customs fees, brokerage fees, duties, and taxes for importation into your country . These additional fees may be collected at time of delivery. We will not refund shipping charges for refused shipments.

The shipping cost does not include any import taxes, and buyers are responsible for customs duties.

Returns:

We do our best to serve our customers the best that we can.

We will refund you if you return the items within 15 days of your receipt of the items for any reason. However, the buyer should make sure that the items returned are in their original conditions. If the items are damaged or lost when they are returned, the buyer will be responsible for such damage or loss, and we will not give the buyer a full refund . The buyer should try to file a claim with the logistic company to recover the cost of damage or loss.

The buyer will be responsible for the shipping fees to return the items.

Warranty & Maintenance:

We offer the 1-month free replacement. Buyers may request for a replacement within 15 days from your receipt of the product . The buyer should return the product in the original conditions to us and should bear the shipping costs for return.

We also provide 12 - month free maintenance. The buyer should return the product in the original conditions to us and should bear the shipping costs for return. If any part is required to be replaced, the buyer should also pay for the costs of the parts to be replaced.

Before returning the items, please confirm the return address and the logistics method with us. After you give the items to the logistic company , please send us the tracking number. As soon as we receive the items, we will repair or exchange them ASAP.

Feedback:

Your satisfaction and positive feedback is very important to us . Please leave positive feedback and 5 stars if you are satisfied with our items and services .

If your order is very big,the price can be discussed,you can buy it first,then give us an message of your target price,we'll give you th e price you wanted,come on,we are your correct choice!!!!

Features of the Linear Bushing.

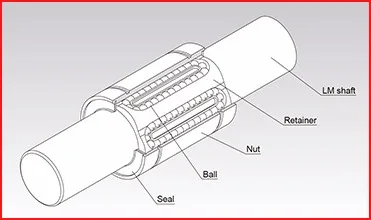

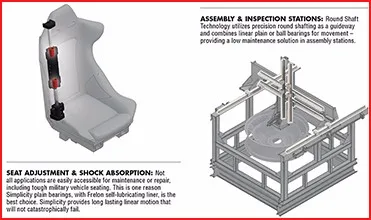

Linear Bushing model LM is a linear motion system used in combination with a cylindrical LM shaft to perform infi nite straight motion. The balls in the loaded area of the nut are in point contact with the LM shaft. This allows straight motion with minimal friction resistance and achieves highly accurate and smooth motion despite the small permissible load.

Fig. Structure of Linear Bushing Model LM-UU

The nut uses high-carbon chromium bearing steel and its outer and inner surfaces are ground after being heat-treated. The Linear Bushing is used in a broad array of applications, such as slide units of precision equipment including OA equipment and peripherals, measuring instruments, automatic recorders and digital 3D measuring instruments, industrial machines including multi-spindle drilling machine, punching press, tool grinder, automatic gas cutting apparatus, printing machine, card or and food packing machine.

Lubrication.

The Linear Bushing requires grease or oil as a lubricant for its operation. sample as Grease Lubrication .

Before mounting the product onto the LM shaft, apply grease to each row of balls inside the Guide

Ball Bushing. There after apply grease as necessary, in accordance with usage and other conditions noted above, or attach housing , or apply grease directly to the LM shaft. We recommend using high-quality lithium-soap group grease No. 2.

Dust prevention.

Entrance of dust or other foreign material into the Linear Bushing will cause abnormal wear or shorten the service life. When entrance of dust or other foreign material is a possibility, it is important to effective seals and/or a dust-control device that meets the service environment conditions. For the Linear Bushing, a special synthetic rubber seal that is highly resistant to wear and a felt seal (highly dust preventive with low seal resistance) are available as contamination protection accessories.

Precautions on Use.

(1) Disassembling each part may cause dust to enter the system or degrade mounting accuracy of parts. Do not disassemble the product.

(2) Take care not to drop or strike the Linear Bushing. Doing so may cause injury or damage. Giving an impact to it could also cause damage to its function even if the product looks intact.

(3) When handling the product, wear protective gloves, safety shoes, etc., as necessary to ensure safety.